Fédération

Galileo Galilei de Grenoble

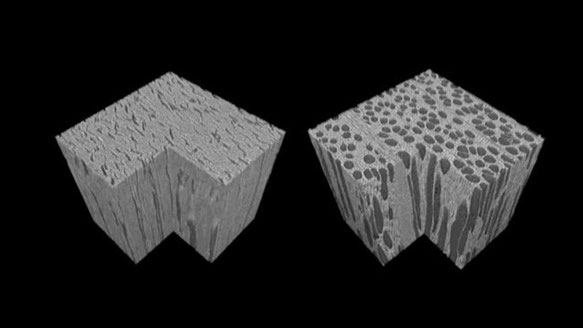

Mécanique et procédés

Fédération

Galileo Galilei de Grenoble

Mécanique et procédés

A la une

La fed3G regroupe les laboratoires grenoblois

de la mécanique et du génie des procédés

LABORATOIRES

en mécanique des fluides et des solides, génie des procédés et physique de la matière molle

CHERCHEURS

enseignants chercheurs, ingénieurs, techniciens, et personnels administratifs

POST-DOCS

et thèses en moyenne sur l'année

STAGES

de master recherche

%

de l'activité en collaboration avec l'industrie

Vous soutenir

Rencontres scientifiques

Equipements communs

Equipements communs

Plateforme d'innovation

Plateforme d'innovation

Opérations inter-labos

Opérations inter-labos

Evènements, conférences

Evènements, conférences